Adaptive Machine Patterns' ⚬Open⚬Ad-Hoc⚬ Modularity Technology Adaptive Machine Patterns (AMP) is working on a groundbreaking modularity framework that embeds a digital twin within each robotic component, enabling truly ad-hoc assembly of robots while preserving predictable performance. Drawing on the core ideas presented in the

ARIA whitepaper on Modularity in Robotics and

Aron's blog post on why Modularity in Robotics is inevitable, AMP's approach translates academic concepts into a practical, openly licensed technology that can be used freely for non-commercial projects.

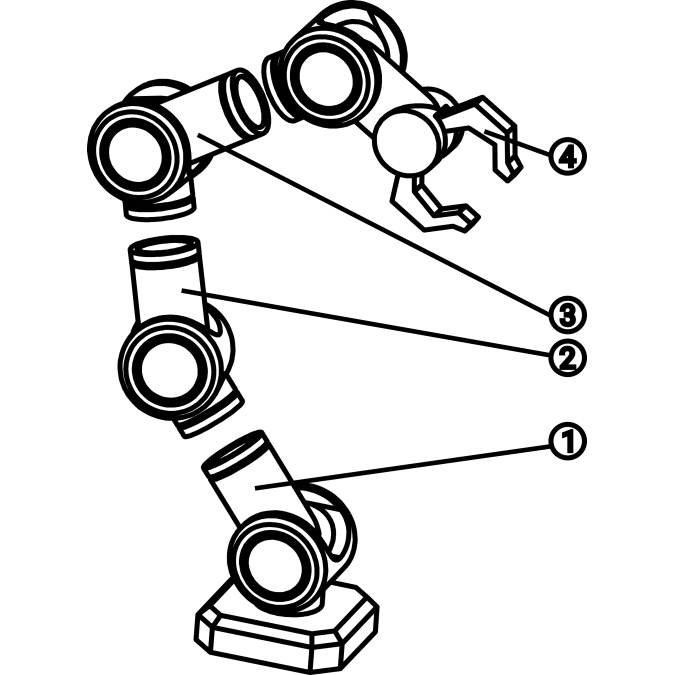

At the heart of the AMP system is a standardized mechanical‑electrical‑communication interface. Every module presents a uniform connector that supplies power, data, and a high-speed bus for real-time coordination. This hardware uniformity mirrors the ARIA recommendation for “plug-and-play” interoperability, allowing designers to mix and match locomotion units, sensor packs, and manipulation arms without custom wiring or firmware rewrites.

What sets AMP apart is the embedded digital twin that lives on each module’s raspberry pi controller. The twin continuously mirrors sensor readings - such as joint torque, temperature, and battery state - and streams this information to a local simulation engine. When modules are combined, their twins exchange semantic descriptors (capability tags, kinematic parameters, resource limits) and instantly synthesize a global system model. This model predicts the assembled robot’s dynamics, energy budget, and collision risk before any motion is executed, echoing Aaron’s demonstration of on-board virtual sandboxes that accelerate configuration testing.

AMP proposes this as an open ad-hoc standard, and is looking for partners released under a permissive, free commercial license for turnovers under $10M USD. By doing so, the company invites researchers, hobbyists, and educational institutions to experiment with modular robotics without navigating proprietary barriers. The standard encourages community-driven extensions - new module types, alternative control algorithms, or bespoke sensor packages - while retaining the safety guarantees of the embedded twins.

In practice, AMP’s technology empowers rapid prototyping: a developer can snap together a wheeled base, a lidar sensor, and a lightweight manipulator, watch the twins negotiate a coherent kinematic model, and launch a validated motion plan within seconds. Because the digital twins operate locally, the system remains resilient to network latency and can function in disconnected environments - a crucial advantage for field robotics and disaster- response scenarios.

By aligning with the scholarly foundations laid out in the ARIA paper and Aaron’s blog, yet extending them with an open, twin-enabled architecture, Adaptive Machine Patterns offers a compelling, community-friendly pathway to the next generation of modular robots. The technology promises to lower entry barriers, accelerate innovation, and foster a collaborative ecosystem where anyone can explore novel robotic configurations without commercial constraints.

Right now its all deeptech - but it'll come out soon -

email us at amp@adaptive-machine-patterns.com to join the revolution!

As an example, the Aron-Ericsson robot arm has been designed with a modular approach - it can be easily extended with new features or components